SteelBandCondenserMount

Problem statement

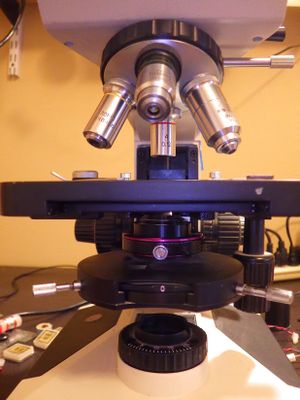

My Chinese trinocular microscope is made reasonably well, but one weakness that I have noticed is the substage condenser mount. The mount is a ring that sits in a rack-and-pinion carriage with two centering screws and one spring pin to center and secure. The problem is that it contains two set screws 180 degrees apart to hold the condenser. Not only does this cause marring to the surface of the condenser optical tube, but it allows the condenser to rock back and forth on the two mounted points. This is even more problematic when you place an asymmetrical condenser into the mount, such as a turret style phase contrast or darkfield condenser. I want a more robust mechanical mounting solution.

Device Description

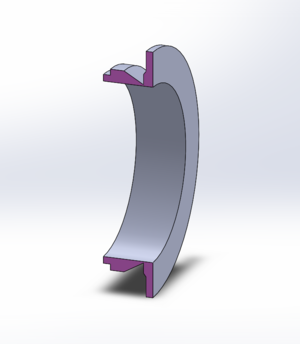

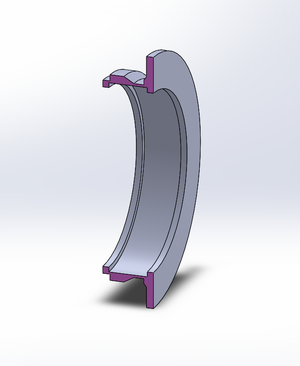

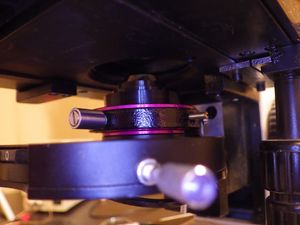

I wanted to machine a groove into the inside surface and add a metal band that the set screws would tighten against. This would allow the clamping to occur over a large circumference of the condenser and thus give a more snug fit without marring or rocking back and forth.

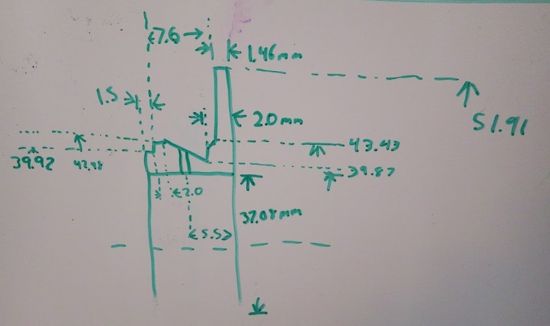

However, the original tin plated brass part was not able to be machined due to the profile being too thin at the extreme of the bevel. This can be seen in the following drawing of the original part where the thickness of the metal is only 1.4mm and is in fact slightly thinner due to difficulty in measuring the diameter of the extreme limit of the bevel (drawing is not to scale). The decision was made to machine a new piece out of aluminum and then anodize it for both beautification as well as abrasion resistance.

Lathe Profile

The part will be closely duplicated out of aluminum but the bevel will be reduced to cover only the area where the centering screws sit. This will reduce the depth of the bevel extreme and preserve enough metal to machine the inner groove to a depth of 1mm. The groove will be 8mm wide (6mm was fabricated). Only one set-screw hole will be needed to cause the band to constrict and press against the condenser surface. I intended to use a 2mm tap but the hole did not tap gracefully due to operator error so the hole was expanded to 2.5mm.

Results

A mistake was made which added 1.5mm to the total length but is largely inconsequential to the operation. The fit is snug and after anodization the fit feel is very smooth with little resistance when inserting a condenser. Purple RIT dye was used to dye the anodization layer and the striking color is a good fit and makes for a race-car like performance part look (priorities people, priorities!).