Difference between revisions of "3D printed LED Ringflash"

(Updated with new development!) |

|||

| Line 1: | Line 1: | ||

| − | |||

==Problem Statement == | ==Problem Statement == | ||

Macro subjects are hard to capture with even light. The solution is to use a ringflash. They are expensive, and I thought it would be fun to design one myself. I wanted to create two different units, one with LED lighting and one with actual flash tubes. I don't want to use digital control. This is both a personal challenge and a robustness requirement. If it "Just Works" (TM) I'll be more likely to use it than if it needs software written and tweaked and uploaded and interfaced with blah. I also want it to be very small so that it can be mounted on the hotshoe. I want something that will have power saving measures if I want to go traveling with it. | Macro subjects are hard to capture with even light. The solution is to use a ringflash. They are expensive, and I thought it would be fun to design one myself. I wanted to create two different units, one with LED lighting and one with actual flash tubes. I don't want to use digital control. This is both a personal challenge and a robustness requirement. If it "Just Works" (TM) I'll be more likely to use it than if it needs software written and tweaked and uploaded and interfaced with blah. I also want it to be very small so that it can be mounted on the hotshoe. I want something that will have power saving measures if I want to go traveling with it. | ||

Revision as of 06:14, 25 March 2014

Problem Statement

Macro subjects are hard to capture with even light. The solution is to use a ringflash. They are expensive, and I thought it would be fun to design one myself. I wanted to create two different units, one with LED lighting and one with actual flash tubes. I don't want to use digital control. This is both a personal challenge and a robustness requirement. If it "Just Works" (TM) I'll be more likely to use it than if it needs software written and tweaked and uploaded and interfaced with blah. I also want it to be very small so that it can be mounted on the hotshoe. I want something that will have power saving measures if I want to go traveling with it.

System Overview

The system consists of a controller PCB, a 3D printed mount for the controller PCB, a power source, a 3D printed structure to mount the lights on, and the lights themselves.

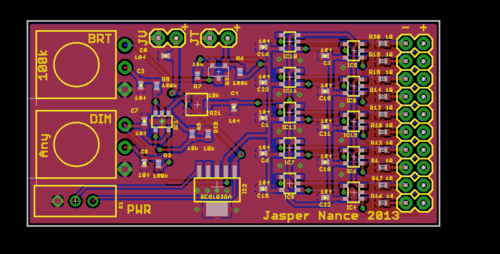

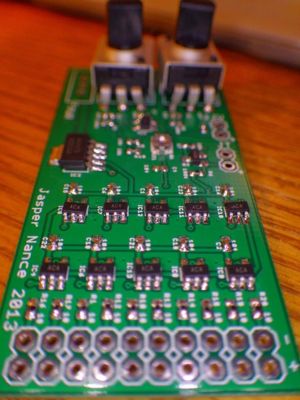

Controller

The controller uses a 5V 500mA REG103GA voltage regulator. I chose 10 LED channels because when I hooked up 5x NTE30071 it wasn't bright enough. More than 10 seems silly and like I should be doing something else with the space, like buck-boosting to a level where the LEDs could be in series. This means that each channel can output up to 50mA.

There are two dials, one sets the "focus" brightness which is always on, and the other sets the "flash" brightness, which is meant to be used for the actual photo.

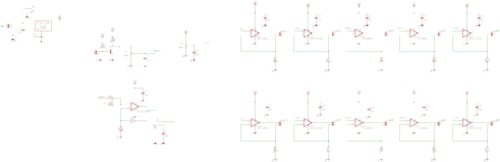

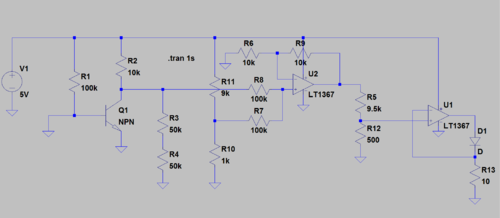

Simulation

The circuit was simulated in LTSpice and checks out.

LEDs

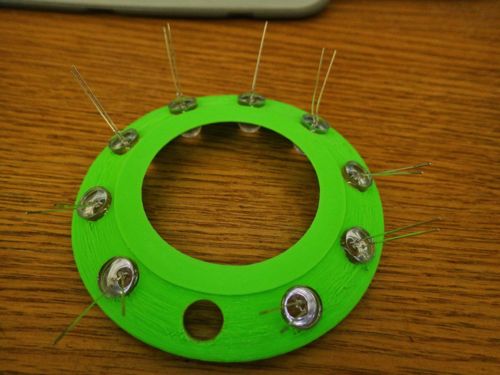

At first I chose NTE30071 LEDs. This seemed like a great solution because they're bright, they run at 25mA, and they have built in 40 degree lenses, so at least for closeup work they should be bright. However, in practice it was found that the light was not even (it was shaped like a halo), the LEDs were not bright enough, and the color temperature varied significantly between LEDs.

For V2 I have ordered some Cree CLA1B-WKW series LEDs which are much brighter (10 lumins instead of 3 at 30mA), have even 120 degree light, and can be run at up to 80mA.

Materials

Reg to use: http://www.ti.com/product/reg103-5 (SOT223-5 package)

Op-amps to use: MCP6L71/1R/2/4 http://ww1.microchip.com/downloads/en/DeviceDoc/22145a.pdf

LEDs to use: NTE30071 http://www.radioshack.com/product/index.jsp?productId=12580024

Trimpot to use for setting reference voltage TC33X-2-103E http://www.digikey.com/product-detail/en/TC33X-2-103E/TC33X-103ECT-ND/612911

Structure

Ring

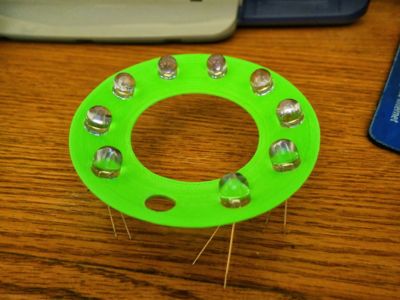

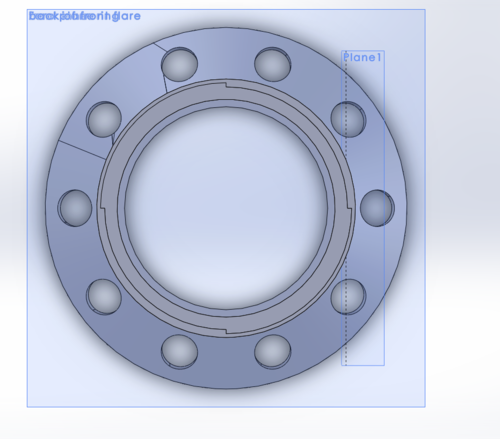

The ring structure was designed to be very basic, it is just a cone that aims the LEDs towards the closest focus spot on my 90mm tamron macro lens. It took about three revisions to find a design that printed well and was robust enough to stand up to testing.

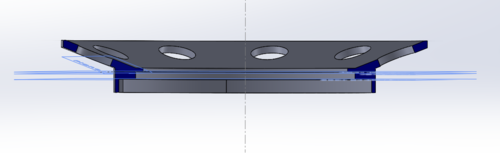

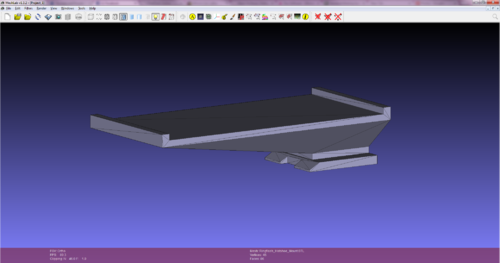

Mount

The hotshoe mount has been designed but not printed yet. Standby for further revisions.